Type generation 2nd of energy storage

SX-60-2

![]()

The second generation of explosion-proof pneumatic hammer (has applied for patent), the tapping force is adjusted by adjusting the air pressure .If the impact force is too small, can not row plugging, can increase the air pressure,on the contrary, the impact is too large ,lower down the pressure. If the customer is not suitable for the choice of the model when the impact force is too strong or insufficient error ,also can adjust the pressure, to solve the air hammer knock force .This structure can change the impact force to ensure the convenience of the selection of air hammer.If the hammer installed on piping can relay several operation at the same time, can greatly reduce the construction cost .

Product features

• Single-impact type, each action produces a shock wave.

• impact and shock interval can be adjusted according to requirements.

• High strength aluminum alloy shell, stainless steel inner wall, light weight, wear resistance.

• By using the principle of energy storage, the instantaneous force of the hammer is improved, and the impact force of the air hammer is improved.

![]()

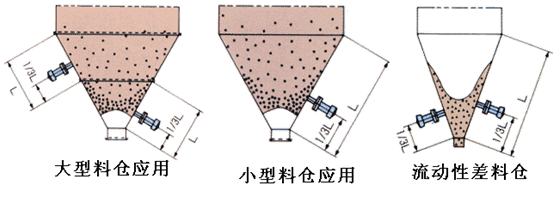

The air hammer output can be used only for a small range for a single impact, the least impact on other equipment ,the impact will not cause the high moisture content of raw materials to have water precipitation or mixture of raw materials for the separation ,it commonly used in tank cleaning, pipeline clogging or elbow, high water content or mixed raw materials or low proportion of material tank

![]()

| Second generation air hammer | Working pressure | Strike period | Air consumption | Impact force | Corresponding hammer | Weight |

| Model | Mpa | Times/Min. | L/time | N.M | Pound | Kg |

| SX-30-2 | 0.3~0.7 | 1~50 | 0.05~0.15 | 5.5~15 | less than 1 | 1.25 |

| SX-40-2 | 0.3~0.7 | 1~40 | 0.15~0.35 | 9.5~27 | 1~1.5 | 2.2 |

| SX-60-2 | 0.3~0.7 | 1~30 | 0.30~0.55 | 20~60 | 1.5~3 | 5.35 |

| SX-80-2 | 0.3~0.7 | 1~20 | 0.40~1.30 | 55~150 | 3.0~5.5 | 11.2 |

| SX-100-2 | 0.3~0.7 | 1~10 | 0.85~1.60 | 100~300 | 7.5~12 | 12.05 |

| SX-125-2 | 0.3~0.7 | 1~5 | 1.10~2.10 | 150~650 | 10~16 | 18.15 |

![]()

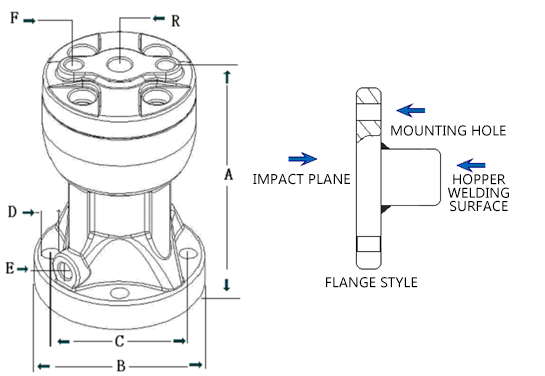

| Second generation air hammer | A | B | C | D | E.R | F |

| Model | mm | mm | mm | mm | G | G |

| SX-30-2 | 115 | 82 | 67 | 9 | 1/4 | 1/8 |

| SX-40-2 | 155 | 98 | 75 | 11 | 1/4 | 1/8 |

| SX-60-2 | 200 | 145 | 105 | 15 | 1/4 | 1/8 |

| SX-80-2 | 275 | 170 | 140 | 17 | 3/8 | |

| SX-100-2 | 310 | 195 | 150 | 17 | 3/8 | |

| SX-125-2 | 320 | 210 | 170 | 24 | 3/8 | 3/8 |

Warning:

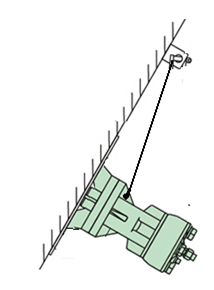

After the installation of the hammer, be sure e to install the Inhaul cable on the body to prevent falling off.

Note:

1 in the installation of the body, please wear a helmet, safety shoes, safety belt, work under the safety environment.

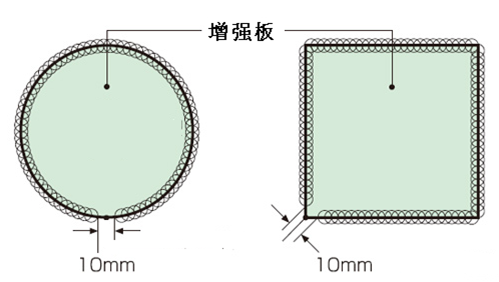

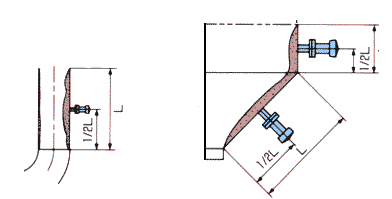

2 When the installation plate is relatively thin, please weld the reinforcement plate, or because of the impact may cause the installation site damage.

3.For welding reinforcement, make sure there is no gap between the reinforcement plate and the hopper ,the exhaust reserved about 10mm, in order to discharge the air ,then the impact force can be fully transmitted .In order to avoid the hopper of damage, please be sure to weld several layers

4. In order to prevent falling off, please use the cable to lift the body and fix it, otherwise it will cause the bolt loosening and falling off

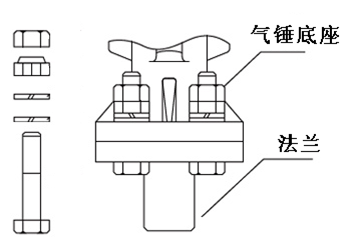

5 When the body and the flange are fixed with bolts, please install the spring washer up and down, and tighten the fastening torque and check regularly

6 piping with air filter before, if there is garbage or dust mixed, may lead to poor operation.

7 do not exceed the required strike force when used, otherwise it may lead to the damage of the bunker or installation.

8 continuous blow, please keep the time setting of more than one second, such as less than 1 second may lead to the occurrence of misoperation.

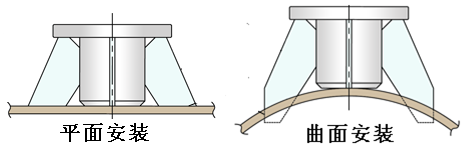

9 please make sure that the striking surface of the mounting flange must be a solid surface. If necessary, please weld reinforced rib (as shown below)

10 the installation of pneumatic hammer suitable position, can play its maximum performance

Relay piping:

1 relay as multiple air hammer pipe directly connected piping, is connected with the relay pipe from the first air hammer to the next relay outlet is connected with an air inlet control mode of air hammer. However, according to the different operating methods, the corresponding maximum number of connections Limited

2 relay piping, endotracheal compressed air in the air tube will cause the air hammer blow. Therefore, the use of pressure and the length of the relay pipe should not exceed the specified value.

3 long distance piping, because of the pressure difference, the strike force will vary, may be appropriate to increase the pressure to make up, to give full play to its stability, can also be set in the vicinity of quick exhaust valve to improve the air hammer impact performance

4 relay piping, please hammer blow interval is set in a second or more, such as relay units increased, please further extend the set time interval.

The use of air hammer piping limit:

Hammer model | SX20-2 | SX30-2 | SX40-2 | SX60-2 | SX80-2 | SX100-2 |

The controller ~ between air hammer | 1 M | 2 M | 3 M | 8 M | 10 M | 10 M |

Pre commissioning and setting:

1 please confirm the attack surface of the flange must be solid plane. The flange of the hammer has bolted,,

2 Please install the air filter before the piping, if there is garbage or dust mixed, may lead to poor operation

3 make sure that the air pressure is 0.3~0.7mpa.

4 normal working pressure is about 0.3~0.7mpa. (when the relay piping is about 0.15 MPa)

5 5 air control valve to hammer the distance farther, the lower part of the pressure of air hammer , therefore, please set the pressure slightly higher.

6 open the hand valve to confirm that the pneumatic hammer can strike normally

7 set the combat strength, please adjust the air valve by 0.05 MPa step by step to achieve the most appropriate attack

8 please tighten the control knob along the clockwise direction, keep in the state. No combat air hammer

9 and then set the control knob clockwise direction (1/4 circle) rotation and set the striking interval

10 set the striking interval, use the locknut to lock the control knob to prevent the loosening of control knob

11 please set the striking interval between 12 times /min~60 times /min

Inspect

The following , please every 2 months check at least once to minimize the problems in use

1 If fixed screw. nut is loose. 2 If welding parts are cracked. 3 If insurance inhaul cable is abnormal

防爆氣動錘專用控製器說明書

本產品是一款防爆氣動錘專用控製器的說明書。閱讀以下的說明能提示您正確而又安全地(dì)使用本產品,並避免他人或自(zì)己受到傷害。

Brief introduction:

Explosion proof controller for pneumatic hammer is a controller that does not need power supply, electromagnetic valve, timer, and other control loops (patent pending)

It can not only control a pneumatic hammer, if the pneumatic hammer equipped with a relay tube, can control the operation of multiple

In the overall equipment installation safety. convenient, very practical.

Explosion proof controller - Specification

防爆控製儀.型號 | 使用環境 | 使用壓力 (mpa) | 使用流體溫度(℃) | 動作次數 (次/min) |

KLSX - 8J | 室(shì)內(nèi)外兼用 | 0.3 ~ 0.7 | 5 ~ 55 | 12 ~ 60 |

Be careful:

1 install the hammer, please use the bolt to prevent accidental damage caused by falling

2 When moving the equipment , please turn off the hand sliding valve side of the ontroller, to prevent accidents caused by sudden start air hammer

3 after the end of the work, please be sure to close the valve , because during the continuous supply of air, air hammer will continue to blow.

4 the pressure is not stable, will make the controller Misact pressure rise - increased number of blows , pressure drop - reduced number of blows, so please install the air pressure regulating valve in front of the controller ,so that controller and air hammer work stable.

5 if you need to install (electric control) as the supply side of the controller, as a timer to use, be sure to use three way solenoid valve, in order to facilitate the discharge of residual air.

Copyright © 2016 Ningbo Kechuan Power Technology Co.,Ltd ,All Rights Reserved.